Detecting flaws or defects in manufactured tubing and metal casting components is essential in any quality assurance process. Finding these defects post-production is critical for any business to ensure quality and save time, money, and resources. The borescope, a remote visual inspection (RVI) instrument used to inspect part internals through small openings, revolutionized tubing and metal casting quality assurance due to its ability to see tiny, hidden defects inside these parts.

Here is an overview of different types of borescopes and their benefits in tubing and metal casting inspection.

Unparalleled Visibility with Borescopes

Borescopes provide an unprecedented level of visibility inside tubing and metal castings. These RVI devices come in different, generally small, diameters to access even the narrowest openings. And with varied probe lengths, inspectors can navigate through complex internals to reach otherwise inaccessible areas.

There are generally three types of borescopes:

Rigid borescopes have a straight and rigid configuration using single or multiple glass lenses to transmit light and imaging. The outer material is usually a resilient metal like stainless steel. Rigid borescopes can be as small as 2.0 mm in diameter.

Image: Richard Wolf Rigid UV Borescope 4 mm

Fiberscopes are semi-rigid or flexible configurations that use glass fibers to transmit light and imaging. These borescopes are bendable, and their outer material can vary from stainless steel to polyurethane to tungsten braiding. Most fiberscopes are non-articulating and can be as small as 0.5 mm in diameter

Image: Fiberscope next to Push Pin

Image: Fiberscope next to Push Pin

Video borescopes have a versatile configuration that transmits light through fiber or LED lamps and captures imaging through a CMOS image sensor, generally at the scope's tip. Video borescopes are usually flexible and have a robust outer coating of stainless steel or tungsten braiding. Many video borescopes have tip articulation control with diameters as small as 1.0 mm.

Image: Video Borescope Inspecting Metal Casting

Image: Video Borescope Inspecting Metal Casting

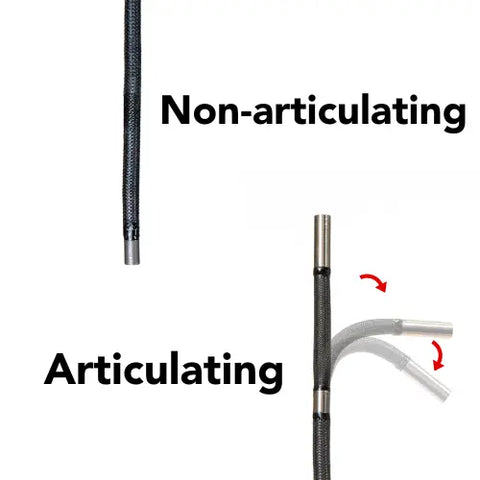

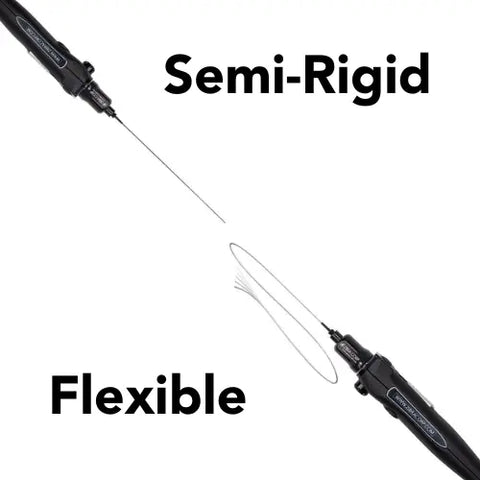

Borescopes vary in diameter and length and can be either semi-rigid or flexible and non-articulating or articulating. Depending on the application, different castings and tubing require different types of borescope stiffnesses, flexibilities, and movement controls. For example, a rigid borescope would better suit a narrow and straight through-hole inspection, while a flexible borescope would do well in a passage with slight bends and turns. Articulation gives an inspector the benefit of controlling the borescope's direction-of-view (DOV) to locate internal defects quickly.

Images : Non-articulating vs Articulating Borescopes, and Semi-rigid vs Flexible Borescope Probes

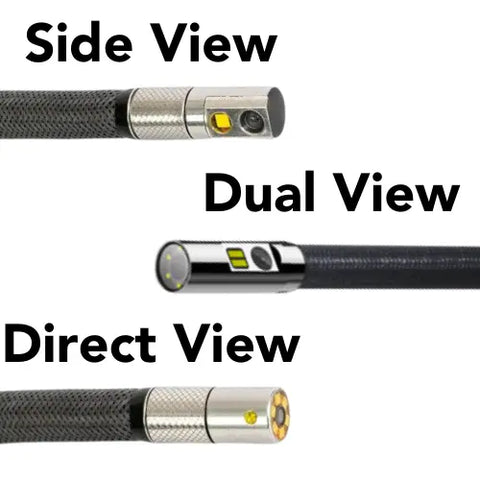

Borescopes also have different direction-of-view (DOV) options: direct view, side view, or even dual view.

Direct View: Direct view is a forward facing view thats 0° degrees from the borescopes tip. This view is used when need to look staight ahead while manuvering through the narrow tubing.

Side View: Side view is an angeld view that offers a 90° view. This view is especially important when inspecting the intereior walls of castings or looking into parts with twists or turns. The side view allows the inspector to see down the other connected passesages where as the direct view may only be able to see the surface of the opening.

Dual View: Dual view is a combination of both views, allowing the inspector to see at both 0° and 90° simultaniously. This borescope tip is invaluable to any industry due to its versatility and ability to examine a tube thouroughly in the first pass.

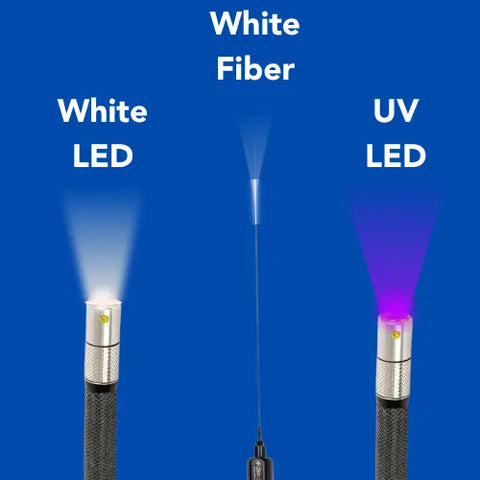

Borescopes offer various lighting choices to ensure illumination inside dark tubing and metal casting part internals. In inspection methods such as fluorescent penetrant inspection (FPI), borescopes use UV LEDs to highlight hairline cracks that might not be otherwise visible. While illumination is critical for borescopes to examine inner surfaces and orbital weld seams, more is needed to achieve the best picture possible.

Image: Lighting Examples white LED, white fiber, UV LED

More than Just Visibility

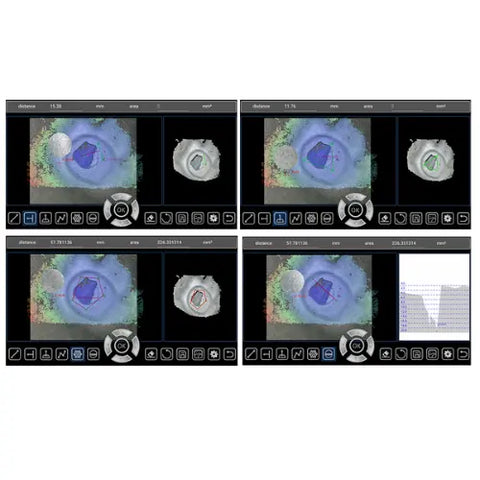

Video borescopes can have advanced features like video processing, temperature sensing, and 3D measurement capabilities. These features provide enhanced images and additional valuable data, enabling ideal quality assurance for tubing and metal castings.

Image: 3D Measurement Borescope Display

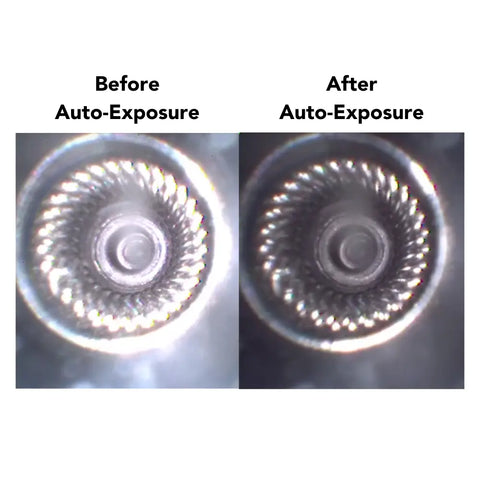

Video processing paired with illumination makes for the best borescope image. On highly reflective internal surfaces (i.e., stainless steel tubing), a bright, white light LED may create a "hot spot" on a borescope image. This washed-out image makes it difficult to identify defects in these parts.

Image: An example of video processing from the Canon Medical SV-2000 Video Borescope

Collecting data, images, and videos captured during visual inspections is critical, so video borescopes have recording capabilities. Inspectors can save and share quality inspection images and data digitally, allowing for enhanced documentation, reporting, analysis, and collaboration. This combination of features makes borescopes indispensable tools for inspecting and assessing the condition of tubing and metal casting components.

Choosing the Best Borescope

When selecting the right borescope for tubing and metal casting inspection, it is essential to consider the manufactured part and what factors of the borescope will best see any potential defects. Considerations and questions to ask:

- Diameter and length - how wide is the opening, and how long is the part?

- Passageway orientation - is the tube or casting passage straight or with bends?

- Surfaces and target sizes - are the internal surfaces highly reflective? What are the expected sizes of the defects?

Answering such questions ensures an inspector can choose the correct borescope for the job. Additionally, assessing a borescope's illumination options, resolution, size, and data collection features to meet the specific requirements of identifying part defects is crucial.

Below are three types of borescopes offered by InterTest:

Versatility and Recording

The Yateks P+ Series is a versatile video borescope with many options, with probe diameters ranging from 1.1 mm to 8.4 mm and available probe lengths up to 10 m.

The Yateks P+ Series also offers 2-way motorized articulation in the 1.7-2.2 mm diameter borescopes and 4-way articulation in models 2.8 mm and up. There are ultraviolet LED, white LED, high-intensity illumination options, and high-definition capabilities. Some other special feature borescopes in this series are the Yateks P+ Series Industrial Video Borescope 3.9 mm OD Direct View - Temperature Sensor with temperature sensing, the Yateks P+ Series Industrial Video Borescope 6.0 mm OD Direct View - Interchangeable Tips with interchangeable tips, and the Yateks P+ Series Industrial Video Borescope 6.0 mm OD Direct View - Far Focus Range with a unique depth of focus.

Ultra Small Diameters

Image: Zibra MillWand HDF and Interchangeable tips

The Zibra MilliWand HDF collection is a small-diameter borescope system with probe diameters from 0.35 mm to 3.1 mm. These borescopes function on an ergonomic and modular platform that can use different semi-rigid and flexible tips of different lengths and diameters. An inspector can quickly change tips depending on the part.

Measurement Data

Image: Yateks Realta 3D Measurement Video Borescope

The Yateks Realta 3D Measurement Video Borescope is a handheld industrial video borescope that utilizes highly accurate 3D measurement software along with 4-way motorized articulation, IP67 probe rating, and an HD touch screen. This series has white LED illumination, direct or side view options, and 4 mm or 6 mm probe diameters. This data is valuable to any quality assurance process for tubing and metal casting.

Borescopes have revolutionized the inspection process for tubing and metal casting applications. Their capacity to provide unparalleled visibility, time and cost efficiency, non-destructive testing, and enhanced documentation solidifies their status as an essential quality assurance tool in the tube and metal casting industries.

InterTest works hard to supply quality borescopes and provide in-depth consultations with customers to pick the best tool. Contact us for your remote visual inspection needs.