Description

Details

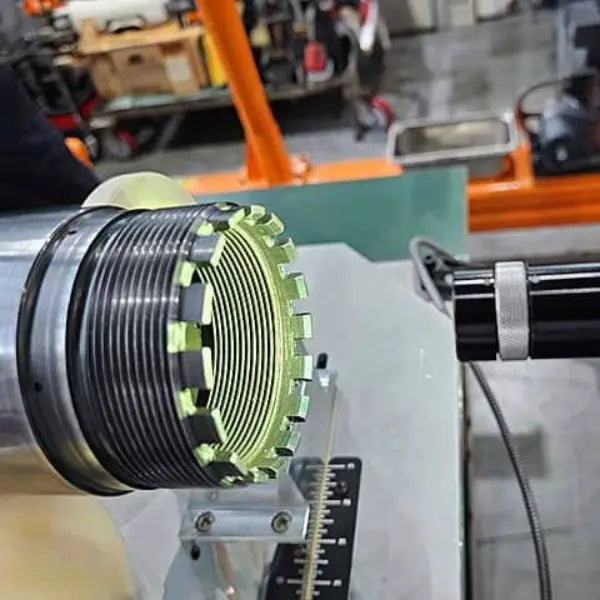

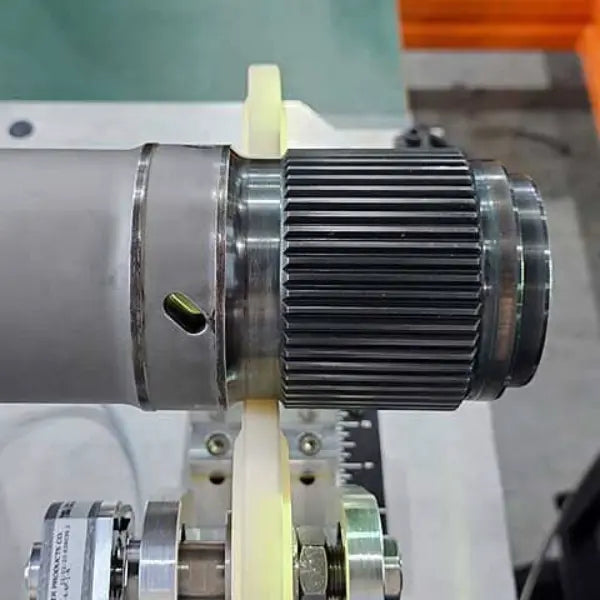

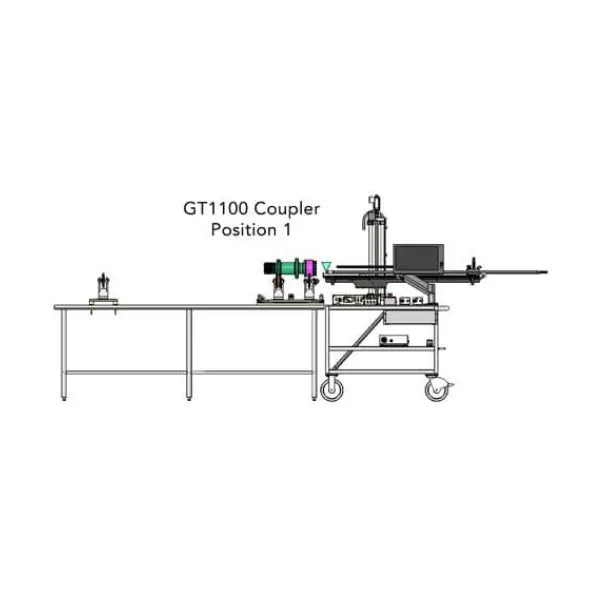

The SeeUV® VIBES® Shaft & Coupler Inspection System (SCIS) is a cart-based remote visual inspection (RVI) system designed to inspect aviation shafts and couplers. It combines a high-definition camera, ultraviolet (UV) and white light illumination, and optional fixtures to achieve repeatable and efficient inspections using fluorescent penetrant inspection (FPI) or magnetic particle inspection (MPI) testing methods. Optional fixtures allow part rotation by hand or motor drive. Position encoders identify the location coordinates of all views.

Illumination Control

Independent white and UV illumination assures a thorough remote visual examination of component internals during white light and ultraviolet inspections. Intensity control of white light and UV operations can be independent or simultaneous. The white and UV illumination is uniform across the field of view and is superior in spectral content and intensity.

Near-Coincident Viewing and Illumination Vectors

Uniform balanced illumination minimizes shadows that interfere with visual examination. The SCIS uses high-grade optics and micro components to ensure the position of the viewing field centers on the projected illumination.

Robust Video Camera

The SCIS employs remotely controlled focus to ensure sharp, high-definition video images. The HD micro camera can capture color video and still images at 1080p60 resolution to ensure high-quality inspection documentation.

Generous Movement Envelope

With manual or optional motor control, the SCIS camera boom can travel 1800 mm horizontal overall range, 1300 mm horizontal slide range, and 500 mm vertical.

Meets the requirements for PWA107540 System, Inspection (FPI) – Video Imaging

Specifications

| Camera Specifications | |

| Image Sensor | 1/6" CMOS 2 MP |

| Video Format | DVI |

| Resolution | 1980H x 1020V effective pixels |

| Shutter | Automatic |

| Operation Temperature | 0°C to 40°C (32°F to 104°F) |

| Illumination System | |

| UV Transmission | 6.5 meter x 3 mm (active diameter) liquid light guide |

| White Light Transmission | 6.5 meter x 3 mm (active diameter) fiberoptic light guide |

| UV Light Output Peak | 365 nm |

| UV Intensity | UV intensity > 2000 µW/cm2 at 76 mm (3.00”) from the target |

| Light Control |

White and UV has a full range of variable intensity Simultaneous and independent operation |

| Camera Head Features | |

| Features | 5 toolless interchangeable optical adapters: 0º, 45º, 60º, 90º, and 90º high magnification |

| Dimensions | 1" (25.4 mm) Diameter |

| Focus | Motorized, remote control |

| Viewing Direction | 0º, 45º, 60º & 90º Narrow, 90º Wide |

| Optical Adapter Specification | |

| Forward (0º) | 64° x 36° (FOV) |

| (45º) | 21° x 11.9° (FOV) |

| (60º) | 21° x 11.9° (FOV) |

| (90º) wide | 64° x 36° (FOV) |

| (90º) narrow | 21° x 11.9° (FOV) |

| Mechanical Specifications | |

| Axis of movement | X-axis (insertion), Y-axis (elevation), and Part Rotation (with optional fixture) |

| Insertion Range (X-axis) |

1300 mm Horizontal slide 1800 mm Overall Pole Horizontal Reach |

| Elevation Range (Y-axis) |

1100 mm minimum 1525 mm maximum |

| Encoding | X-axis, Y-axis, rotation with optional fixture |

| Encoding Resolution | ± 0.1 cm |

| Cart (Height) | 860 mm welded steel, black powder coated |

| Display | |

| Model | Marshall 17.3” Pro LCD |

| Controller Power | 110VAC (220VAC) optional |