Automotive Casting Inspection

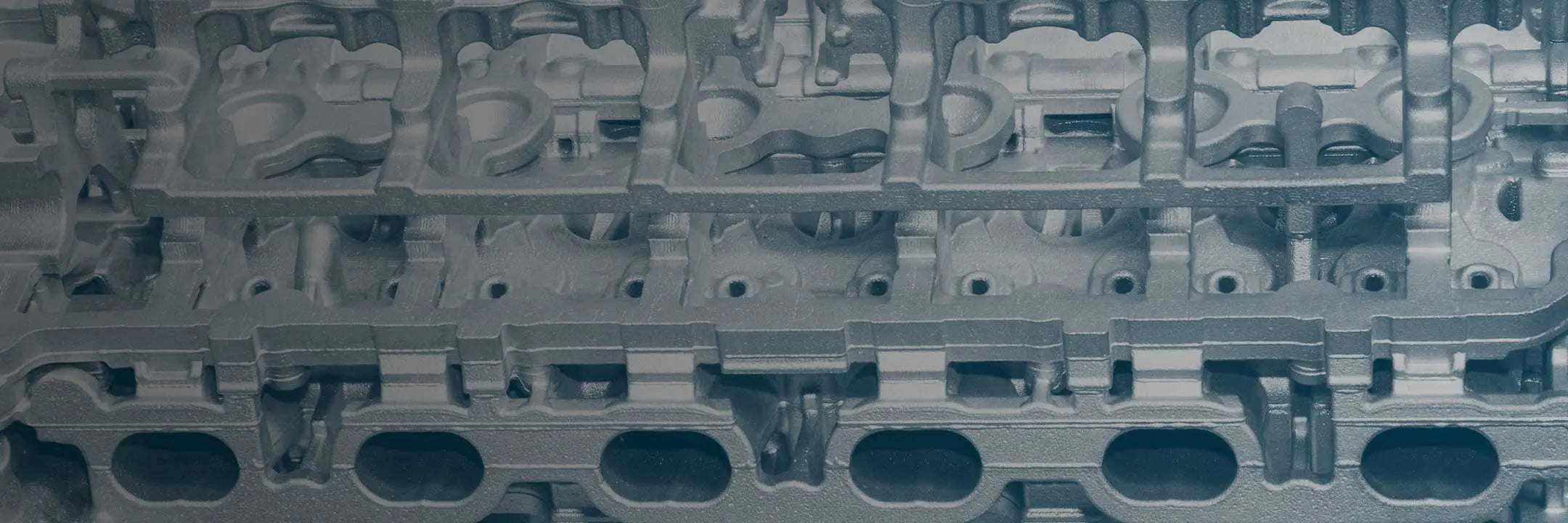

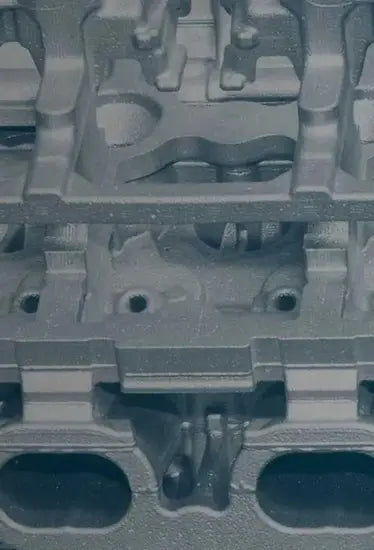

Automotive castings are traditionally solid aluminum or cast iron parts typically made by the die-casting process. The die-casting process forces molten metal into a unique steel mold to form a specific automotive component with complex internal cavities and passages. This casting method used in the automotive industry produces high precision, low weight, and pressure tightness parts used in engines and other auto parts.

Common automotive casting components are cam housings, intake manifolds, balance shaft housings, and wheels. These parts are prime examples of utilizing die-casting methods because machining their complex geometries from a solid block would be costly and inefficient.

RVI Technology Innovation

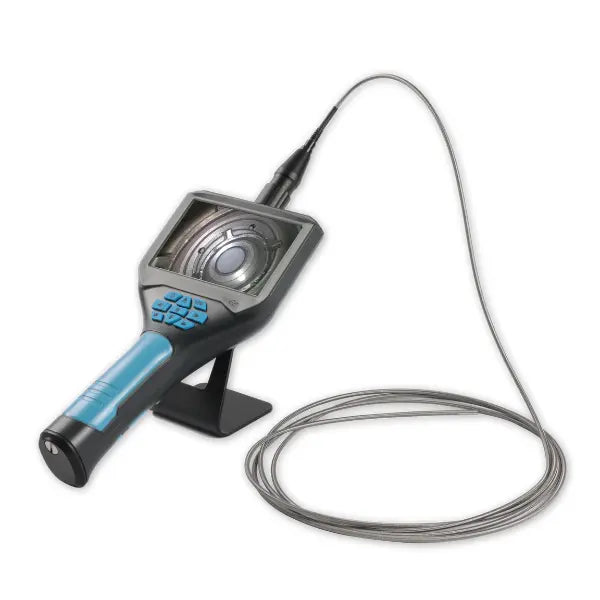

Continuous innovation of RVI technology advance the critical inspection capabilities that many industry sectors depend on for quality measures. This article dives into the advancements of video borescopes, live weld-monitoring cameras, and pan-tilt-zoom (PTZ) cameras.

Read ArticleAutomotive Casting Inspection

Automotive Casting Inspection

Learn how InterTest, Inc. products are involved in the daily quality assurance procedures of the automotive industry.

Call InterTest, Inc. today for a free consultation on your automotive casting inspection application.