Maintenance Repair and Overhaul (MRO) in Aviation

What is maintenance repair and overhaul in aviation? MRO either refers to heavy maintenance, repairs, and overhaul of aviation components, or a certified facility that perform these services.

The Federal Aviation Administration (FAA) requires commercial aircraft to undergo MRO work (60, 72, 96, 120-month inspections or A, B, C, D checks) at a Certified Repair Station (CRS).

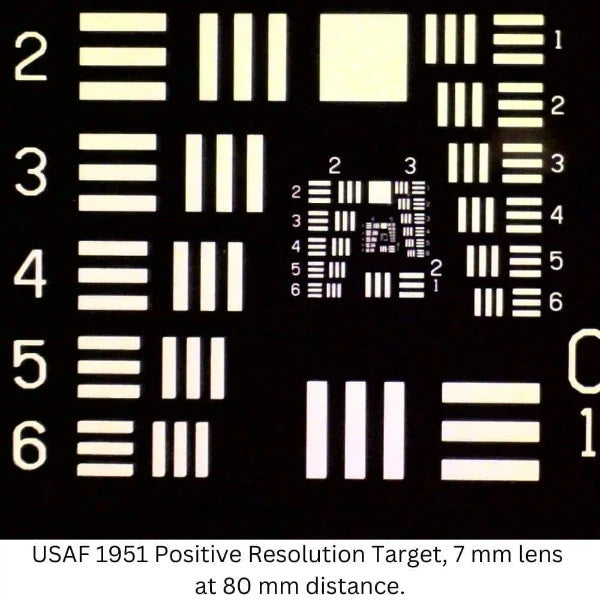

Remote visual inspections of aircraft engine spools, drums, shafts, couplers, and landing gear components are critical in MRO.

Check out InterTest's industrial camera inspection systems designed to meet or exceed FAA and MRO facility inspection credentials:

MRO in Aviation

From routine checks to extensive overhauls, every aspect of an aircraft's maintenance ensures its airworthiness and operational integrity. As air travel continues to expand and aircrafts age, the demand for MRO services is expected to soar even higher, emphasizing the critical role they play in ensuring the future of aviation safety and efficiency.

Read ArticleAircraft Component Inspection

Aircraft Component Inspection

Need inspection in maintenance repair and overhaul? Get in touch with InterTest, Inc. for a free consultation on how SeeUV and UV borescopes/video borescopes can ensure component quality at your OEM/MRO facilities today.

Contact Us