Zibra HDV Borescope

- Flexible and small enough to fit into openings 1.5 mm in diameter

- On-screen display includes saved image gallery or capture on removable drive

- Rugged and designed to withstand repeated use

Yateks B+ Portable Series

- Handheld video borescope for viewing/ recording

- Slip ring option for unrestricted 360-degree probe rotation

- Direct and side view options

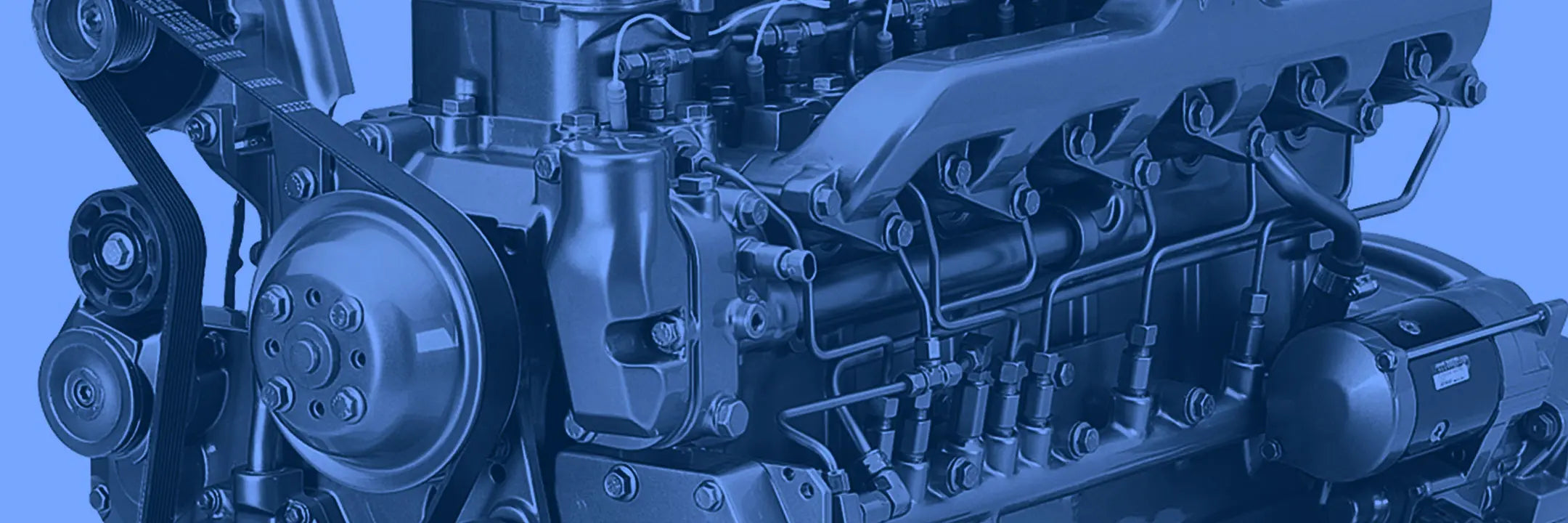

Diesel Engine Overview

Like the gasoline engine, the diesel engine is an internal combustion engine that uses high air compression and fuel injection to convert fuel into energy. Diesel fuel-burning requires higher air compression for ignition than gasoline, so the diesel engine must be made with more robust components to withstand its process.

Common components in diesel engines include:

- Valves

- Cylinders

- Pistons

Diesel engine mechanics and manufacturing quality technicians need to perform remote visual inpsection (RVI) to look for cracks, porosity, metal burrs, and other signs of wear. They use quality management systems that require these components to have visual documentation to identify nonconforming products and the need for servicing. Prior to the availability of borescopes and video borescopes, visual inspection of diesel engines could only be performed by taking apart the engine and viewing each part with a naked eye.

Intertest, Inc. video borescope products streamline quality assessments and documentation without time-consuming engine dismantling.

See products for diesel engine inspection:

Diesel Engine Inspection

Need a Boroscope Solution?

Intertest Inc. is a provider of specialized visual inspection instruments ideal for internal diesel engine components without dismantling. Call us today for a free consultation on what inspection system is best for your diesel engine inspection.

Contact Us