For over 50 years, inspectors have been using rigid borescopes to ensure the quality in small, manufactured and industrial components. These tiny and precise viewing instruments built of glass and metal proved to best way to perform crucial inspections - until now. Now with 21st century micro camera sensors, the rigid borescope makes a forward leap in innovation.

Intertest, Inc. proudly introduces the new Yateks B+ Benchtop Series Rigid Borescope System, a well-overdue update to the world of rigid borescope platforms. Rigid borescopes have been used in industrial quality control for over 50 years because of their superb optical clarity and easy, repeatable handling for quality inspections of industrial components. Traditional rigid borescopes have been constructed using high-precision optical lenses, to allow the user to clearly view the internal surfaces and objects of components.

The new Yateks B+ Benchtop Series Rigid Borescope System is the next innovative leap in borescope inspection technology.

This system eliminates the optical lens system entirely and places a micro camera sensor at the distal end of the borescope.

The value-added features for the Yateks B+ Benchtop Series Rigid Borescope System include:

- Durable, easily-detachable and cost-effective borescope tips

- An organized inspection environment with no need for costly auxiliary instrumentation such as light sources, light guides, adapters and cameras

- Dynamic light adjustments using the camera sensor that eliminates bothersome glare on inspection surfaces

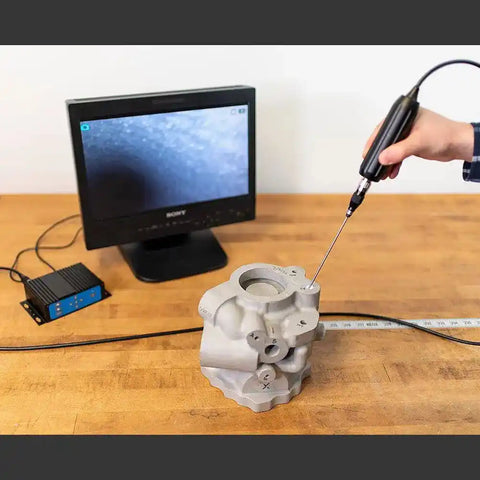

Pictured left: The Yateks Rigid Borescope benchtop setup with monitor.

Pictured right: The Yateks B+ Portable Series Monitor

The comprehensive system consists of the iShot® R-Series Rigid Borescope tips (available in forward and side configurations in various diameters and lengths), a standard Yateks Benchtop/Desktop Video Borescope Handle attachment allowing for easy swapping of borescope tips, and an Yateks Desktop Camera Controller (left image) or a portable, handheld version (right image) which provides controls and imaging. Optional accessories include backup borescope tips and sliding fixtures for methodical and repeatable quality inspections as seen in the video below: