INTERTEST CUSTOM ENGINEERING SOLUTION

iGRAB™ 1/2" OD

FOSAR VACUUM TOOL

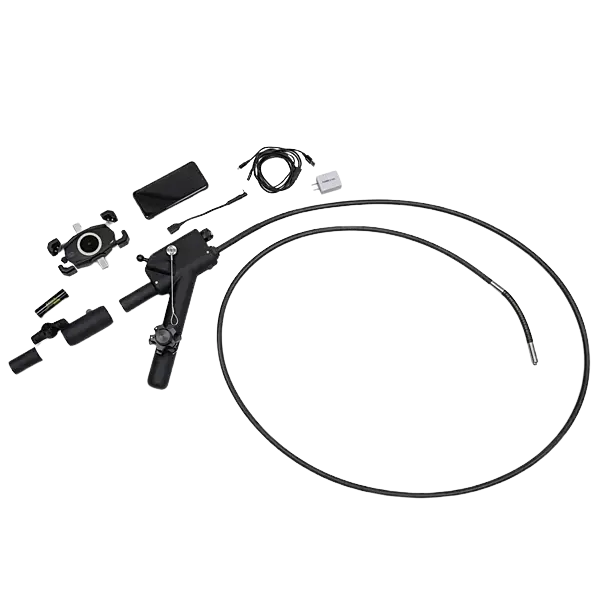

An articulating vacuum retrieval tool with camera

At a Glance

CHALLENGE

What needed to be overcome?

- Remove small granular buildup from turbines

- Articulate to maneuver into tight spaces

- Have full foriegn object search and retrieval (FOSAR) capability

DEVELOPMENT

What needed to be designed?

- Vacuum suction needed to be at the core of the design to remove tiny sediment buildup

- A requirement of enough tensile strength to push through narrow passages

- A modern OS and recording device

SOLUTION

What was the end product?

- A 1/2-inch outer diameter articulating guide tube with 4-way articulation

- Compatibility with an Android device for viewing and recording

- Suction Efficacy proven for FOSAR at 0.25" hose ID

-

THE CHALLENGE

In this situation, an aerospace and aviation customer specializing in manufacturing and maintenance needed a retrieval tool to remove small granular buildup from turbines and jet engines during maintenance and repair overhaul (MRO) procedures.

Retrieval tools are ideal devices for retrieving foreign object debris (FOD) in areas that are not easily accessible. FOD can range from tiny granules or buildup to mid-sized metal shavings or screws, to large wrenches or tools that were dropped during a maintenance procedure. Due to the various types of FOD, there are different retrieval tools and jaws specialized to remove specific types of FOD in a reliable and safe manner.

-

DEVELOPMENT & INNOVATION

This application mandated the need for a foreign object search and retrieval (FOSAR) tool that would enable the operator to illuminate and visually identify the FOD being retrieved. The device also required sufficient tensile strength to be pushed through the narrow passageways while still being able to articulate at the tip, allowing for precise movements.

Due to the nature and location of the FOD, jaw sets like the spoons or cups would not reliably retrieve the tiny sediment efficiently, so a vacuum-based tool would need to be custom-engineered for a safe and reliable retrieval procedure during the aircraft component inspections.

-

THE SOLUTION

InterTest's custom engineering solution was a vacuum-articulating guide tube with an outer diameter of 0.5 inches and a suction tube with an inner diameter of 0.25 inches. The entire probe extended over 9.5 feet, featuring a 6-inch articulating tip. A chamfered tip was installed to prevent the probe getting stuck when pushing forward in its environment.

This device features a robust probe design that can withstand multiple inspection procedures and a portable monitor. While initially designed with the aviation and aerospace industries in mind, this device has numerous applications in various other industries.

Project Results

-

A vacuum FOSAR tool capable of removing granular FOD materials

-

Full articulation and vision control/recording operation

-

Versatile in applications and industries requiring FOD removal